Yanmar® diesel engines are known for their efficiency and durability in both marine and industrial environments. Whether you’re powering a construction machine, generator, or marine vessel, maintaining your Yanmar engine with the right parts and practices is key to maximizing its lifespan and performance. At Maxiforce, we provide premium-quality Yanmar diesel engine parts and technical support to help you repair with confidence.

1. Identify Your Yanmar Engine Model Correctly

The first step in any repair or maintenance job is confirming your exact engine model. Maxiforce covers a wide range of Yanmar engine models, including:

- Marine Engines: 3TNV84, 4TNV84, 3TNV88, 4TNV88, 4TNV94, 4TNV98, 4TNV106T

- Industrial Engines: TK486, 4TNE88, 4TNE94, 4TNE106D, 4TNE106T, and others used in Thermo King, Komatsu, and agricultural equipment

Accurate model identification helps ensure you choose compatible components, reducing the risk of mismatches or further engine issues.

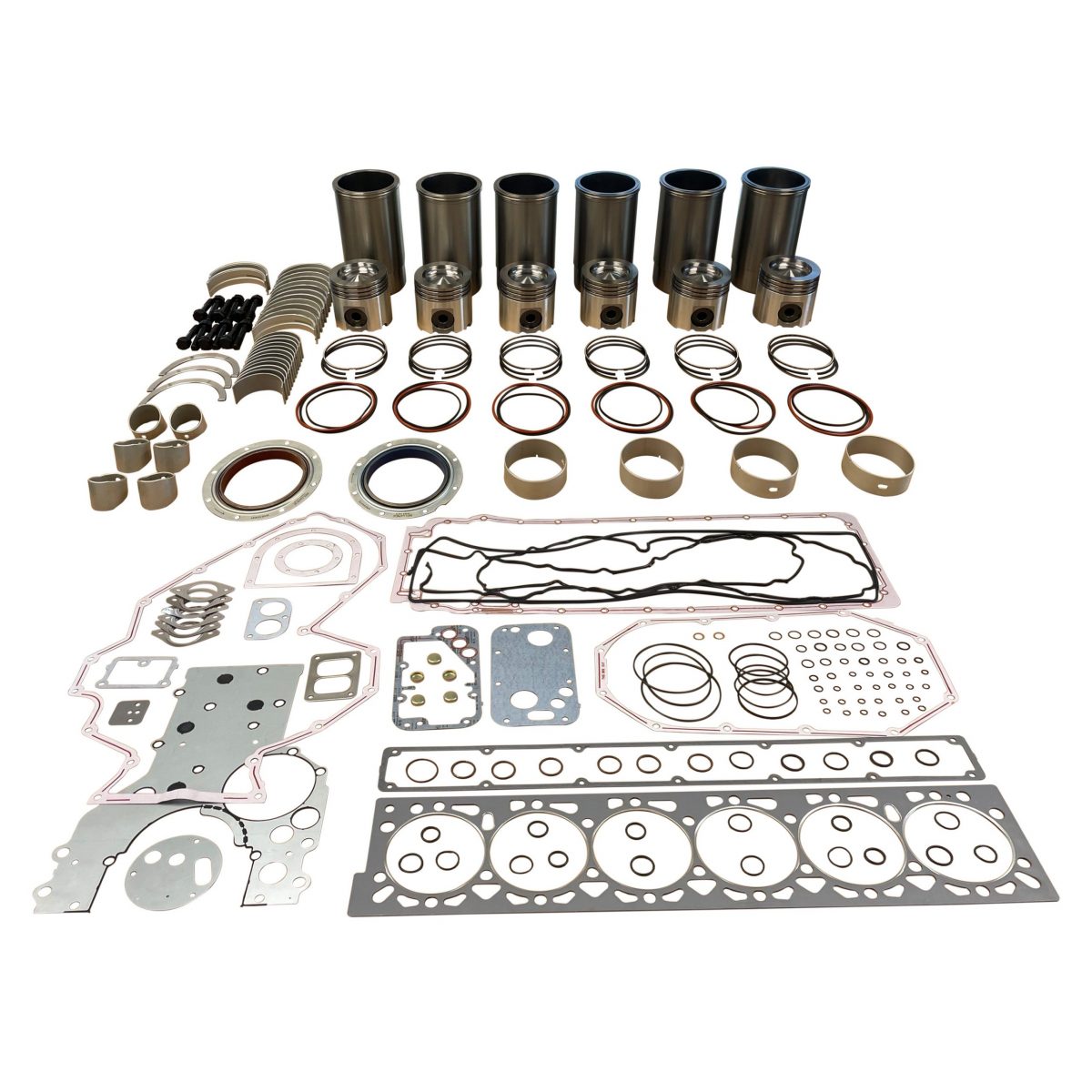

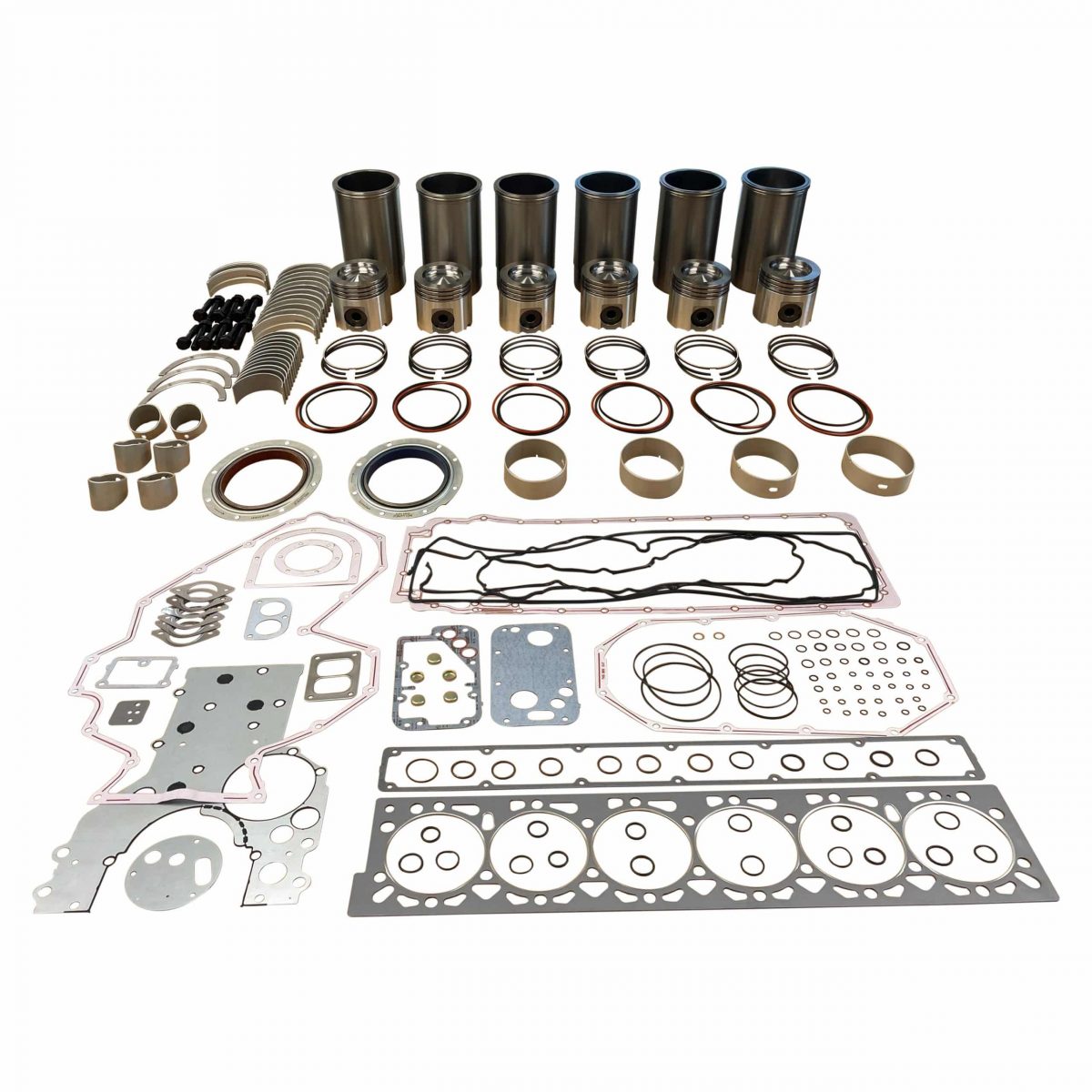

2. Choose Complete Overhaul Kits When Appropriate

If your engine shows signs of severe wear—such as increased oil consumption, low compression, or power loss—a full rebuild may be needed. Maxiforce offers some of the most complete Yanmar overhaul kits on the market. These include essentials like:

- Pistons and ring sets

- Crankshafts and camshafts

- Gaskets and seals

- Oil pumps and water pumps

- Fuel injectors and glow plugs

Using a full kit ensures every critical system in your engine is refreshed and working in harmony.

3. Watch for Marine-Specific Stress and Corrosion

Marine engines, especially in saltwater environments, are more prone to corrosion and cooling system issues. Keep an eye on water pumps, thermostats, and oil coolers for signs of rust, mineral buildup, or leaks. Maxiforce stocks essential marine engine components such as:

- Oil Cooler – Y129508-33030

- Water Pump – Y129001-42004 (3TNV88/4TNV88)

- Thermostats – Y121850-49811, Y121850-49801, Y129155-49801

- Glow Plugs – Y129008-77800, Y129155-77800

Regularly replacing these parts can prevent overheating and major failures.

4. Don’t Overlook Fuel and Oil System Components

Yanmar engines rely on precise fuel delivery and clean lubrication. Over time, wear in these systems can affect performance. Consider replacing:

- Fuel Transfer Pumps – e.g., Y129100-52101-Z, Y119225-52102

- Injectors – Y729503-53100, Y729004-53101

- Oil Pumps – Y129001-32001, Y123900-32001, Y129908-32060

Installing new, high-quality components helps maintain fuel efficiency and prolong engine life.

5. Use Only Quality Replacement Parts

Maxiforce parts are engineered to meet or exceed original performance standards. With ISO 9001:2015 certification and over 75 years of combined industry experience, our quality control and testing protocols ensure your engine runs reliably—even in harsh marine and industrial conditions.

Conclusion

Yanmar engines are built tough, but like any hardworking system, they require regular attention and quality components to stay in peak condition. Whether you’re performing routine maintenance or a full overhaul, Maxiforce provides the dependable Yanmar diesel engine parts you need to get the job done right.

Explore our full range of Yanmar engine parts here, and take advantage of immediate shipping and expert technical support. With Maxiforce, you’re never alone in your repair journey.