John Deere 6068 6.8T/H Piston (m) RE527039 Tier 2 & Tier 3 (2)

PRINT THIS PAGE

AVAILABLE EQUIPMENT MODELS

Engine Series:

PowerTech

Engine Model:

6068T/H

Engine Desc:

For Tier 2 & Tier 3 Applications

Engine Data:

2 Valve per Cylinder

CODE 4839

Engine Info:

6 Cyl

Engine Dimensions:

Bore: 4.19 in / 106.5 mm

Pin Ø: 1.6250 in / (+/- .0002) = 41mm

Con Rod (m):

R500335 (Fractured)

Piston (m):

RE527039

- 1110D

- 1110E

- 1210E

- 1410D

- 1510E

- 970D

- 1070D

- 1070E

- 1490D

- 640H

- 648GIII

- 648H

- 540H

- 548H

- 648L

- 748H

- 6530 PREM

- 7230 PREM

- 6630 PREM

- 7330 PREM

- 6830 PREM

- 7430 PREM

- 6930 PREM

- 7530 PREM

- 624KII

- 624KR

- 640GIII

- 624J

- 624K

- 6068HF285

- 6068HDW65

- 6068HDW67

- 6068HDW73

- 6068HDW76

- 6068HDW79

- 6068HRT80

- 6068HTJ75

- 6068HTJ85

- 6068HTJ86

- 6068HTJ88

- 6068HL486

- 6068HDW89

- 6068HL280

- 6068HTJ56

- 6068HT063

- 6068HT066

- 6068HT069

- 6068HT072

- 6068HRW74

- 6068HRW72

- 6068HN054

- 6068HL287

- 6068HL284

- 6068HL282

- 6068HL281

- 6068HFG82

- 6068HE051

- 6068HE050

- 6068HDW74

- 6068HDW70

- 6068HCQ82

- 6068HFC28

- HJW205T6

CLOSE

Equipment Models

Forwarder

Harvester

Skidders

Farm Tractors

Wheel Loaders

engine model

Hi Power-Gensets

-

1) Engine O/H KitTRE540226 Click to view kit contentCLOSEItem #:Quantity:Description:TR1140826BUSHING, CON ROD PT 41TR1198741BUSHING, CAMSHAFTTR50112412CAPSCREW, CON ROD, P.T.TRE445741SEAL, OIL REARTRE5055151SEAL, CRANKSHAFT FRONTTRE3161712SEAL, VALVE STEMTRE5326311GASKET, O/H SET PTTRE5360836KIT, PISTON/LINERTRE651656BRG, MAIN STDTRE651681BRG, MAIN THRUST STDTRE659086BRG, CON ROD STD2) Engine I/F KitTIK540226 Click to view kit contentSpec Sheet - 6068T 24 ValveCLOSEItem #:Quantity:Description:TR1233541GASKET, OIL PAN P.T.TR50112412CAPSCREW, CON ROD, P.T.TRE3161712SEAL, VALVE STEMTRE5328411GASKET, HEAD SET PTTRE5360836KIT, PISTON/LINERTRE651656BRG, MAIN STDTRE651681BRG, MAIN THRUST STDTRE659086BRG, CON ROD STD

1) Engine O/H KitTRE540226 Click to view kit contentCLOSEItem #:Quantity:Description:TR1140826BUSHING, CON ROD PT 41TR1198741BUSHING, CAMSHAFTTR50112412CAPSCREW, CON ROD, P.T.TRE445741SEAL, OIL REARTRE5055151SEAL, CRANKSHAFT FRONTTRE3161712SEAL, VALVE STEMTRE5326311GASKET, O/H SET PTTRE5360836KIT, PISTON/LINERTRE651656BRG, MAIN STDTRE651681BRG, MAIN THRUST STDTRE659086BRG, CON ROD STD2) Engine I/F KitTIK540226 Click to view kit contentSpec Sheet - 6068T 24 ValveCLOSEItem #:Quantity:Description:TR1233541GASKET, OIL PAN P.T.TR50112412CAPSCREW, CON ROD, P.T.TRE3161712SEAL, VALVE STEMTRE5328411GASKET, HEAD SET PTTRE5360836KIT, PISTON/LINERTRE651656BRG, MAIN STDTRE651681BRG, MAIN THRUST STDTRE659086BRG, CON ROD STD -

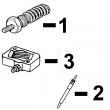

Piston-Liner KitTRE536083Consists of:a) TRE527039 b) TRE527844 c) TR502755 d) TR116397 e) TAR65507 f) TR54114

Piston-Liner KitTRE536083Consists of:a) TRE527039 b) TRE527844 c) TR502755 d) TR116397 e) TAR65507 f) TR54114 -

Main BearingTRE65165 Std. TRE65911 0.010 TRE65165B 0.020 (2)Use 6

Main BearingTRE65165 Std. TRE65911 0.010 TRE65165B 0.020 (2)Use 6 -

Thrust BearingTRE65168 Std. TRE65912 0.010 TRE65168B 0.020 (2)Use 1

Thrust BearingTRE65168 Std. TRE65912 0.010 TRE65168B 0.020 (2)Use 1 -

Con Rod BearingTRE65908 Std. TRE65909 0.010 TRE65908B 0.020 (2)Use 6

Con Rod BearingTRE65908 Std. TRE65909 0.010 TRE65908B 0.020 (2)Use 6 -

1) Front SealTRE505515 (1)2) Rear SealTRE445743) Ring GearTR114282 (5) TR28811 (5)4) CrankshaftTRE515785 (3) TRE505921 (4)5) Crankshaft GearTR120631 30T

1) Front SealTRE505515 (1)2) Rear SealTRE445743) Ring GearTR114282 (5) TR28811 (5)4) CrankshaftTRE515785 (3) TRE505921 (4)5) Crankshaft GearTR120631 30T -

1) O/H Gasket SetTRE532631 (10)2) Head Gasket SetTRE5328413) Head GasketTR1165164) Oil Pan GasketTR521498 (5) TR123354 (5)5) Rocker Cover GskTR524496 TR524497

1) O/H Gasket SetTRE532631 (10)2) Head Gasket SetTRE5328413) Head GasketTR1165164) Oil Pan GasketTR521498 (5) TR123354 (5)5) Rocker Cover GskTR524496 TR524497 -

1) Bush, Con RodTR114082 x62) Bolt, Con RodTR501124 x123) Bush, CamshaftTR119874 x14) Cam FollowerTR123565 x12

1) Bush, Con RodTR114082 x62) Bolt, Con RodTR501124 x123) Bush, CamshaftTR119874 x14) Cam FollowerTR123565 x12 -

1) Cyl Hd Cap ScrewTR85363 (5) TR502511 (5)2) Belt TensionerTRE5180973) Con RodTRE5006084) Oil CoolerTRE59296 (5 Plates) TRE56690 (7 Plates) TRE59298 (9 Plates)

1) Cyl Hd Cap ScrewTR85363 (5) TR502511 (5)2) Belt TensionerTRE5180973) Con RodTRE5006084) Oil CoolerTRE59296 (5 Plates) TRE56690 (7 Plates) TRE59298 (9 Plates) -

1) Water PumpTRE500734 (11) TRE500734P (11) TRE546918 (5)2) Water Pump CovTRE5085663) Water Pump GskTR123417 (5)4) Pump, OilTRE504914 (5) TRE521756 (5)5) Water Pump HousingTR1216346) Oil Pump GearTR120638 30T

1) Water PumpTRE500734 (11) TRE500734P (11) TRE546918 (5)2) Water Pump CovTRE5085663) Water Pump GskTR123417 (5)4) Pump, OilTRE504914 (5) TRE521756 (5)5) Water Pump HousingTR1216346) Oil Pump GearTR120638 30T

Valve Section

-

Valve, IntakeTR98062 Std. (5)

-

Valve, Exhaust

-

1) Insert, Valve In2) Insert, Valve Ex

-

1) Seal, ValveTRE31617 x12 (5)2) Lock, ValveTR91889 x24 (5)

-

1) Spring, ValveTR26125 x12 (5)

-

1) ThermostatTRE522076 180° F (5) TRE538289 180º F (5) TRE64354 180° F (5)2) Thermostat CoverTR501130 (5)3) Water Temp SensorTRE51774 (5)4) Water Temp SensorTRE52722 (5)5) Oil Pressure SensorTRE167207 (5)6) Crankshaft SensorTRE519144 (5)7) Fuel Pressure SensorTRE522794 (5) TRE520930 (5)8) Temperature SensorTRE522823 (5)

1) ThermostatTRE522076 180° F (5) TRE538289 180º F (5) TRE64354 180° F (5)2) Thermostat CoverTR501130 (5)3) Water Temp SensorTRE51774 (5)4) Water Temp SensorTRE52722 (5)5) Oil Pressure SensorTRE167207 (5)6) Crankshaft SensorTRE519144 (5)7) Fuel Pressure SensorTRE522794 (5) TRE520930 (5)8) Temperature SensorTRE522823 (5) -

1) Fuel Transfer PumpTRE66153 (6) TRE68345 (7) TRE502513 (8) TRE517230 (5)2) InjectorTDZ100211 (5) TDZ100212 (5) TDZ100217 (5) TRE516540 (5)3) Injection Pump GearTR502541 30T (5)4) Idler Gear, LowerTRE56369 43T (5)5) Pressure Relief ValveTRE516335 (5)6) Suction Control ValveTDZ111135 (5) TDZ111136 (5) TDZ111137 (5) TDZ111141 (5)

1) Fuel Transfer PumpTRE66153 (6) TRE68345 (7) TRE502513 (8) TRE517230 (5)2) InjectorTDZ100211 (5) TDZ100212 (5) TDZ100217 (5) TRE516540 (5)3) Injection Pump GearTR502541 30T (5)4) Idler Gear, LowerTRE56369 43T (5)5) Pressure Relief ValveTRE516335 (5)6) Suction Control ValveTDZ111135 (5) TDZ111136 (5) TDZ111137 (5) TDZ111141 (5) -

Glow Plug1) TRE502079 (11 V) 2) TRE504580 x6 (10 V)3) Air HeaterTRE502668 (12 V)

Glow Plug1) TRE502079 (11 V) 2) TRE504580 x6 (10 V)3) Air HeaterTRE502668 (12 V) -

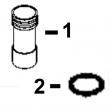

1) Injector TubeTRE543935 x62) Injector O-RingTRE528349 TRE530609

1) Injector TubeTRE543935 x62) Injector O-RingTRE528349 TRE530609 -

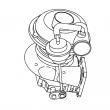

TurbochargerTRE508657 (5) TRE550932 (5)

TurbochargerTRE508657 (5) TRE550932 (5)

(1): 1 Piece Unitized Seal and Wearsleeve; Replaces TRE59810, RE538097.

(2): Proper bearing journal radius must be maintained during the machining of the crankshaft to ensure proper operation.

(3): Crankshaft (m) R116076, Straight Nose.

(4): Crankshaft (m) R503470, Taper Nose.

(5): Check application for proper usage.

(6): Line Connections are both threaded.

(7): Line Connections are one hose barb & one threaded.

(8): Line Connections are two hose barbs.

(10): Our gasket sets do not include the front and rear crankshaft seals

(11): TRE500734 supplied with a cast iron impeller; TRE500734P supplied with a resin impeller.