Your agricultural diesel engine is the heartbeat of your farming operation. From powering tractors and harvesters to irrigation systems and loaders, it keeps your equipment productive day in and day out. But like any hardworking machine, even the most reliable diesel engine will eventually need replacement parts to maintain peak performance. Ignoring the warning signs can lead to unexpected breakdowns, costly repairs, and lost productivity during the busiest seasons.

In this guide, we’ll cover the top signs that your agricultural diesel engine may need replacement parts—and how Maxiforce can help keep your equipment running strong.

1. Hard Starts or Failure to Start

If your diesel engine struggles to start or requires multiple attempts, it may be a sign of worn fuel injectors, weak glow plugs, or a failing starter motor. Inconsistent or difficult starting is often the first indicator that critical parts are wearing down and need replacement.

2. Loss of Power During Operation

When your tractor or combine begins to lose pulling power, the issue could point to failing pistons, cylinder liners, or fuel system components. Reduced performance under load often signals that your engine is no longer operating at full efficiency, making timely replacement parts essential to restore productivity.

3. Excessive Exhaust Smoke

Blue, black, or white exhaust smoke isn’t just unpleasant—it’s a warning sign.

- Blue smoke indicates oil burning due to worn piston rings or valve seals.

- Black smoke suggests a fuel system issue such as clogged injectors or a dirty air filter.

- White smoke points to coolant entering the combustion chamber, often caused by a damaged head gasket.

Each of these issues can be addressed with high-quality replacement parts before they turn into major failures.

4. Overheating Issues

Frequent overheating in your agricultural diesel engine can result from worn-out cooling system components such as water pumps, thermostats, or radiators. Ignoring these issues risks long-term damage to the engine block or head. Replacing defective parts quickly keeps your equipment safe and reliable.

5. Unusual Noises or Vibrations

Knocking, grinding, or rattling noises coming from your diesel engine should never be ignored. These sounds may indicate failing bearings, worn pistons, or loose internal components. Addressing them early with replacement parts can prevent catastrophic damage and costly downtime.

6. Rising Fuel Consumption

If your engine starts using more fuel than normal without an increase in workload, it’s a sign of inefficiency. Problems with injectors, filters, or piston wear can all contribute to reduced fuel economy. Replacing these parts can restore performance and keep fuel costs under control.

7. Visible Leaks or Frequent Fluid Loss

Oil or coolant leaks around the engine are clear warning signs that seals, gaskets, or hoses need replacing. Left unchecked, leaks can lead to overheating, low lubrication, and eventual engine failure.

Keep Your Farm Running with Maxiforce Parts

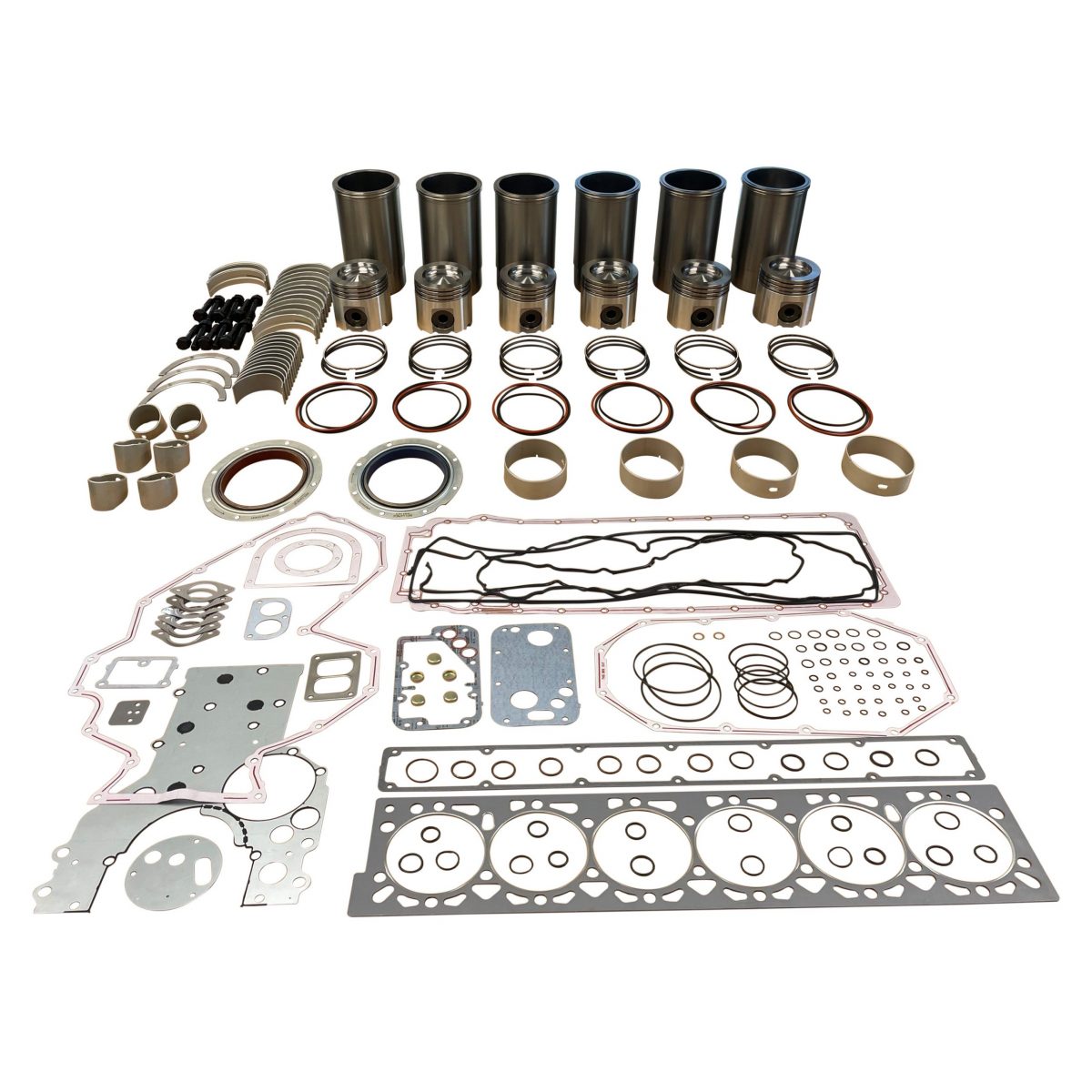

Your agricultural diesel engine is too important to risk on worn or failing components. From pistons and liners to engine rebuild kits and fuel system parts, Maxiforce provides farmers with the high-quality replacement parts needed to keep John Deere®, Perkins®, Caterpillar®, and other engines operating at peak performance.

Need help identifying the right parts for your equipment? Contact Maxiforce today to speak with our knowledgeable team and keep your farm running smoothly season after season.

FAQs About Agricultural Diesel Engine Parts

1. How often should I replace parts in my agricultural diesel engine?

Replacement intervals depend on usage, but regular maintenance checks will help identify worn components before they fail.

2. Are Maxiforce parts compatible with John Deere® and Perkins® engines?

Yes, Maxiforce provides a wide range of high-quality parts designed for John Deere®, Perkins®, Caterpillar®, Yanmar®, and other major engine brands.

3. What’s the benefit of replacing parts early?

Replacing worn parts early prevents major engine failures, reduces downtime during planting or harvesting seasons, and saves money in the long run.

4. Can I get help choosing the right replacement parts?

Absolutely. The Maxiforce team is available to guide you through selecting the correct parts for your specific engine model and application.

Final Thoughts

Don’t let failing engine parts slow down your farming operations. Maxiforce is committed to helping farmers around the world keep their agricultural equipment performing at its best. Contact us today for expert advice and access to our full inventory of replacement diesel engine parts.